In pursuit of continuous improvement, several Industries and businesses across the globe have adopted Kaizen as an integral part of their operational processes. ‘Kaizen’ is a Japanese word meaning ‘improvement’. It is a Japanese philosophy referring to activities for continuous improvement of functions and processes of an organisation and personal efficiency too. Implementation of Kaizen philosophy is a regular sight in various manufacturing industries, logistics companies, and the like.

Cognizant of the improved efficiency and productivity, The Akshaya Patra Foundation, an NGO in India has adopted Kaizen in its processes. Akshaya Patra is a mid-day meal NGO serving school lunch to 17,12,460 children in 36 kitchens across 12 states of India, every day. For this, the NGO operates centralised kitchens in urban and semi-urban areas, and decentralised kitchens in remote areas. The centralised kitchens have the capacity to cook up to 1 lakh meals each day and serves meals to schools located in its area and neighbouring areas, whereas decentralised kitchens concentrate in providing meals to located within its immediate reach. In order to enhance its efficiency and increase its productivity, Akshaya Patra implements Kaizen in its kitchen operations. This method is followed in each kitchen unit to innovate, rethink, and reassess work, and implement efficient procedures.

To appreciate and encourage the use of Kaizen philosophy, the Foundation regularly recognises and rewards innovative practices. Here are some of the improvements from across different kitchens of this NGO in India:

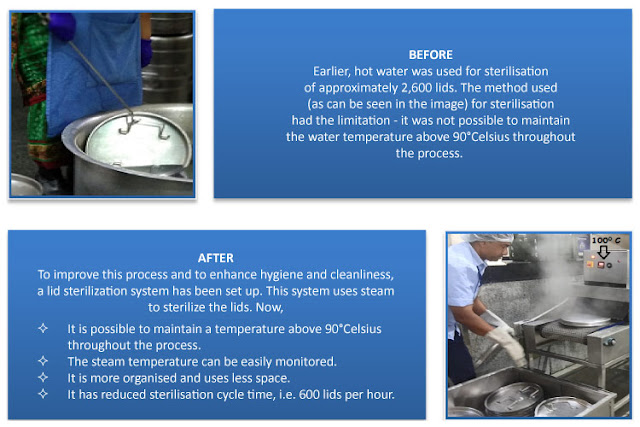

Lid steriliser at Vadodara kitchen, Ahmedabad

Tool shadow board at Vasanthapura kitchen, Bengaluru

Increase in per hour roti production batches at Ajmer kitchen, Rajasthan

Air powered grease gun at Bellary kitchen, Karnataka

The above-mentioned were just a few mentions of the many Kaizen interventions in the kitchens of Akshaya Patra. The Foundation is a recipient of Indizen Award, CII National Food Safety Award, Lean Six Sigma Award, Quality Mark Award, and Asian MAKE Award by CII. Aside from Kaizen, this NGO in India also adopts Six Sigma methodologies and undertakes several Continuous Improvement Projects so that resources can be maximised, productivity can be doubled, quality can be enhanced, and service to children can be multiplied.

0 comments:

Post a Comment